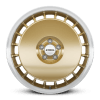

R60-blue JB/FC

Jetblack-front diamond cut

The RONAL GROUP sets an excellent example in terms of environmental and social responsibility with the RONAL R60-blue wheel. The product innovation is very energy efficient with 100% green power and it is manufactured under optimal working conditions. R60-blue wheels stand out due to weight reduction, provision of material and optimizations in the production process, resulting in considerably reduced impact on the environmental. On the one hand the wheel is an ambassador and milestone for our new PLANBLUE sustainability concept and, on the other hand it is a pioneer for a new, environmentally friendly generation of wheels.

The design is available for various electric and hybrid vehicles in the jetblack-front-diamond cut style but it is also suitable for many other vehicles.

The RONAL GROUP sets an excellent example in terms of environmental and social responsibility with the RONAL R60-blue wheel. The product innovation is very energy efficient with 100% green power and it is manufactured under optimal working conditions. R60-blue wheels stand out due to weight reduction, provision of material and optimizations in the production process, resulting in considerably reduced impact on the environmental. On the one hand the wheel is an ambassador and milestone for our new PLANBLUE sustainability concept and, on the other hand it is a pioneer for a new, environmentally friendly generation of wheels.

The design is available for various electric and hybrid vehicles in the jetblack-front-diamond cut style but it is also suitable for many other vehicles.

Variants

N/A