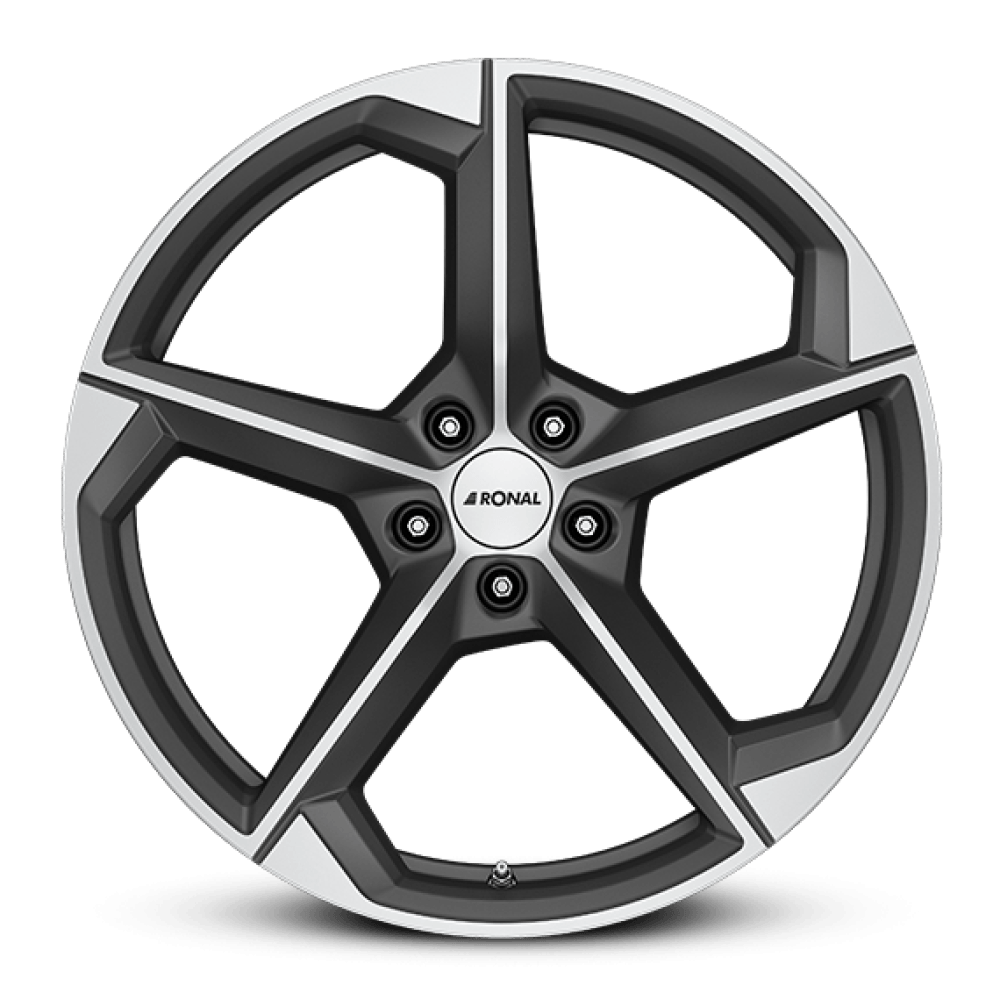

R66 OGM/FC

Orbit grey-matt-front diamond cut

The RONAL R66 design has a new glossy surface and is characterized by elegance and playful asymmetry. The innovative surface in Orbit gray-matt-front diamond cut, is a real eye-catcher and impresses from a distance thanks to its matt look and shiny surfaces over the full length of the spoke.

The RONAL R66 design has a new glossy surface and is characterized by elegance and playful asymmetry. The innovative surface in Orbit gray-matt-front diamond cut, is a real eye-catcher and impresses from a distance thanks to its matt look and shiny surfaces over the full length of the spoke.

Variants