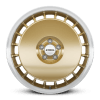

R67 JB red

Jetblack

It doesn’t always have to be a new car… the R67 with self-adhesive applications is the perfect option for giving your ride a fresh custom look. The colorful extras, design elements in an aero style in red or gray allow for perfect air inlet, offering that extra sporty touch. Simple installation regardless of the rolling direction ensures a flawless appearance, completing the vehicle’s outfit. Ideal for mid-range sports cars.

It doesn’t always have to be a new car… the R67 with self-adhesive applications is the perfect option for giving your ride a fresh custom look. The colorful extras, design elements in an aero style in red or gray allow for perfect air inlet, offering that extra sporty touch. Simple installation regardless of the rolling direction ensures a flawless appearance, completing the vehicle’s outfit. Ideal for mid-range sports cars.

Variants